- Vavdi, Rajkot, Gujarat

- GST NO. : 24ACLFS9099N1Z1

- +91-9227171209, +91-9825369897

Industrial Machines

Leading Manufacturers, Exporters, Wholesaler and Retailer of Flask Vacuum Machine, Gold Bar Making Machine, Induction Based Bearing Shrink Fitting Machine, Induction Hardening Machine, Induction Heating Machine, Jewellery 3D Printer CAD Cam Machine, Magnetic Polisher Machine and Mini Induction Brazing Machine from Rajkot.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Application | Industrial |

| Voltage | 230 Volt AC |

| Type | Vacuum Machine |

| Country of Origin | India |

| Power Supply | Single Phase |

| Absorbed Power | 400w |

| Flask Vacuum Machine | 600x450x1025 Approx |

| Brand Name | SHAPET |

| Product Code | CS110 |

| Port | icd khodiyar |

| Payment Terms | L/C |

| Delivery Time | 1 WEEK |

Preferred Buyer From

| Location | Worldwide |

The Flask Vacuum Machine is a versatile product designed to meet your vacuum sealing needs. With its compact size and powerful vacuum pump, this machine is perfect for preserving food freshness, marinating meats, or storing delicate items. The user-friendly interface allows for easy operation, while the durable construction ensures long-lasting performance. Whether you are a home cook or a professional chef, the Flask Vacuum Machine is a reliable tool to help you extend the shelf life of your favorite foods and keep them fresh for longer.

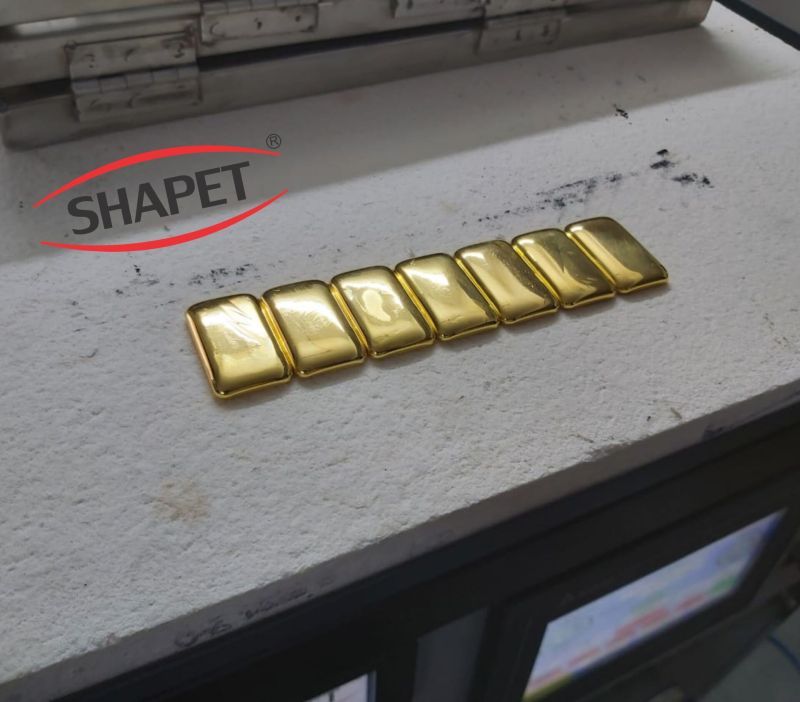

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Condition | New |

| Automatic Grade | Fully Automatic |

| Power Source | Elecric |

| Application | Gold Bar Making |

| Type | Gold Making Machine, Gold Bar Making Machine |

| Country of Origin | India |

| Warrenty | 1year |

| Control system | PLC |

| Absorbed Power | 45 kw |

| Maximum Capacity | 1 Pcs O 1kg Bar or 4 Pcs of 100grm Bar |

| Brand Name | SHAPET |

Preferred Buyer From

| Location | Worldwide |

Get ready to revolutionize your gold bar-making process with the Shapet Gold Bar-Making Machine! This state-of-the-art, fully automatic casting machine can accommodate up to 4 pieces of 1KG gold or 20 pieces of 100 GRM gold at once, making it the perfect choice for large-scale production. With its advanced PLC touchscreen control, you can easily monitor and adjust the casting process to ensure consistent, high-quality results. And thanks to its vacuum operation, you can say goodbye to ripples and oxidation, preserving the purity of your precious metals. Trust us, with 24 hours of continuous operation, this gold bar-making machine is a game-changer for any serious producer. Order now and experience the future of bullion casting

The gold bar casting machine is a specialized equipment used in the production of gold bars. It is designed to melt and cast gold into various shapes and sizes. The machine is made up of a furnace, a casting chamber, and a cooling system. The furnace is used to melt the gold, which is then poured into the casting chamber. The casting chamber is where the molten gold is shaped into bars using molds. Once the gold has solidified, it is cooled down using the cooling system. The gold bar casting machine is an essential tool in the gold industry as it allows for the efficient production of high-quality gold bars.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Mild Steel |

| Finishing | Paint Coating |

| Driven Type | Electric |

| Shape | Rectangular |

| Color | Light Blue |

| Condition | New |

| Warranty | 1yrs |

| Country of Origin | India |

| Brand Name | SHAPET |

Preferred Buyer From

| Location | Worldwide |

Shapet Induction is expert at devising customized systems. They come complete with induction heater, coil, fixtures, cooling unit and temperature control. The machines can be automated, semi-automated or manual. Compared to conventional preheating and stress relieving methods, induction heating offers numerous advantages, including improved heat uniformity and quality, reduced cycle time, and lower consumables costs. Induction heating is also safe, reliable and easy to use, and scores higher than alternative technologies .in power efficiency and versatility

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Color | Grey |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | 1-3kw |

| Application | Industrial |

| Voltage | 440 VAC,440 Volt AC |

| Type | Induction Hardening Machine |

| Warranty | 1year |

| Country of Origin | India |

| Power Supply | Three Phase |

| Absorbed Power | 25 kW to 35 kW |

| Brand Name | SHAPET |

| Product Code | CS1011 |

| Port | icd khodiyar |

| Payment Terms | L/C |

| Delivery Time | 1 WEEK |

Preferred Buyer From

| Location | Worldwide |

Shapet Induction Hardening Machine is a type of induction furnace that produces heat on the principle of electromagnetic induction. A metal job is placed to be heated inside Induction Coil and quenched to dive, a needed transformation that makes metal hardened and brittle.

We are manufacturers of Induction Hardening machines with high efficiency, durability, and reliability utilizing quality materials. We are manufacturing and supplying a broad array of Induction Hardening Machines, which are used for surface and through-hardening. Along with the offered induction hardening machine, we give solutions to auto parts, and hand tools industries also We are manufacturing customized machines according to application.

Typical applications of induction hardening include Gears, Shafts, Axles, Cam lobes, Stampings, and Spindles, mostly Symmetrical parts. Induction hardening is used to strengthen a specific area of a part. Single-piece, surface hardening of selective areas.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Application | Industrial Use |

| Heating Capacity | 20 KW |

| Type | Induction Heating Unit |

| Phase | Three Phase |

| Warranty | 1 Year |

| Country of Origin | India |

| Brand Name | SHAPET |

Preferred Buyer From

| Location | Worldwide |

Shapet Induction Hardening Machine is a type of induction furnace that produces heat on the principle of electromagnetic induction. A metal job is placed to be heated inside Induction Coil and quenched to dive, a needed transformation that makes metal hardened and brittle.

We are manufacturers of Induction Hardening machines with high efficiency, durability, and reliability utilizing quality materials. We are manufacturing and supplying a broad array of Induction Hardening Machines, which are used for surface and through-hardening. Along with the offered induction hardening machine, we give solutions to auto parts, and hand tools industries also We are manufacturing customized machines according to application.

Typical applications of induction hardening include Gears, Shafts, Axles, Cam lobes, Stampings, and Spindles, mostly Symmetrical parts. Induction hardening is used to strengthen a specific area of a part. Single-piece, surface hardening of selective areas.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Power Source | 1 PH |

| Usage/Application | 3D Wax Pic Making |

| Display Type | PLC |

| Technology | DLP |

| Country of Origin | Made In India |

| Industry | Jewellery |

| Connectivity | USB |

| File Format Supported | STL |

| Brand Name | SHAPET |

Preferred Buyer From

| Location | Worldwide |

Introducing Virinchi DLP printers Which uses high power intensity ultraviolet light engine with Full HD resolution processing DLP Technology.Print 5 times faster than SLA printer and with 5000 hours of projector life print freely without tension of replacement.

Print detailed accurate part with an accuracy of 25 micron with smooth surface finish.with combination of high speed brushless motor and high intensity light engine printing process is faster than ever before. Super Active Carbon Filter ensure odor and toxic free environment in printing process.

Application

Jwellery Casting

Dental Casting

Industrial Prototype Parts

Virinchi MINI

4.3 Inch HD Display for print status indication

Dedicated Pause and Stop buttons

Stepper motor with precise movement

Active Carbon Air Filter

Full Metal Design for rigid Operations

Platform Size: 90mm × 50mm × 150mm

Print Speed: 10 to 15 Regular size Rings per hour

Virinchi

4.3 Inch HD Display for print status indication

Dedicated Pause and Stop buttons

Stepper motor with precise movement

Active Carbon Air Filter

Full Metal Design for rigid Operations

Platform Size: 120mm × 68mm × 200mm

Print Speed: 20 to 25 Regular size Rings per hour

Virinchi Plus

4.3 Inch HD Display for print status indication

Dedicated Pause and Stop buttons

Stepper motor with precise movement

Active Carbon Air Filter

Full Metal Design for rigid Operations

Platform Size: 150mm × 84mm × 200mm

Print Speed: 35 to 40 Regular size Rings per hour

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | 1-3kw |

| Application | Polishing Parts |

| Voltage | 230 Vac |

| Type | Magnetic Polisher Machine |

| Warranty | 1year |

| Country of Origin | India |

| Phase | Single Phase |

| Operating Mode | Manual |

| Absorbed Power | 0.5 HP |

| Media | Steel 0.5*5 (800 Gms) |

| Brand Name | SHAPET |

Preferred Buyer From

| Location | Worldwide |

A magnetic polisher speeds up the polishing process considerably. However, there are still a number of steps required to polish a piece and to maintain the machine.. These instructions are geared toward the smaller sized machine. For the larger machines, more items can be polished using less time. 1 First, use a fine jeweler’s file to remove scratches, excess solder, and other blemishes from the metal. Try to remove as many blemishes as possible with the file. This is especially important because the machine is not designed to remove scratches. 2 Make sure pieces are clean. For example, cast pieces should be free of all investment. (Ammonia and an old, soft tooth brush work well for cleaning investment off charms.)

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Driven Type | Electric |

| Color | Grey |

| Condition | New |

| Automatic Grade | Automatic |

| Application | For Brazing Material |

| Voltage | 220V |

| Warranty | 1year |

| Country of Origin | India |

| Brand Name | SHAPET |

Preferred Buyer From

| Location | Worldwide |

The mini induction brazing machine is a compact and efficient tool used for joining metal components. It utilizes the principle of electromagnetic induction to generate heat and melt a filler material, which is then used to bond the workpieces together. This machine is designed for precision and versatility, making it suitable for various applications in industries such as automotive, aerospace, and electronics. With its small size and user-friendly interface, the mini induction brazing machine offers easy operation and precise control over the brazing process. It is equipped with advanced features such as power adjustment, and automatic shutdown, ensuring consistent and reliable results. The machine is also equipped with safety mechanisms. Overall, the mini induction brazing machine is a reliable and efficient solution for small-scale brazing operations, providing high-quality and durable joints.